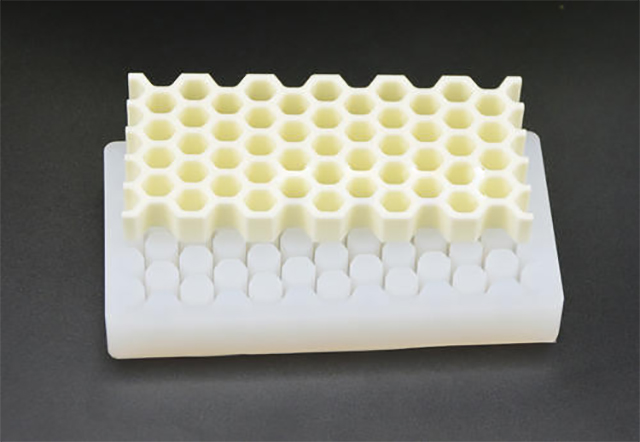

Robot headgear

The playground robot headgear customized for the customer is placed on a simple manual inner mold, and the mouth and eye opening and closing are being tested

2020/10/9 9:59:13

There are a lot of process details in the front end of the production of silica gel products, and QC at the back end of the product is also a lot of common detection problems, hot formed product surface adhesive for a lot of silica gel products manufacturers have a headache, then how to professional silica gel products manufacturers to solve?

Problems for the silicone products manufacturer, all kinds of bad is not the reason for the raw material color mixing, molding technology and mould design is reasonable, and the product of stick in the first place in the mold die to find the main reason, in the process of production of silicone products after the vulcanization is introduced two mold mold core need to set aside to thoroughly will flash and raw rubber from the product, because the product inside groove die structure makes it hard for take out the product in the second vulcanization is the groove in the rubber processing clean; Secondly, there is no accurate control of the weight of raw materials during production, so that too much raw glue flows into the mold and there are no cracks in the mold, and the cleaning of the mold after the mold is not clean enough, which leads to the raw glue and the rough edges of the mold. The last important reason is that many silica gel products manufacturers for a large number of products need to catch up with the output, the vulcanization time will reduce the product surface soft, coupled with the structure of the mold, so the emergence of rubber products close to the reason.

The playground robot headgear customized for the customer is placed on a simple manual inner mold, and the mouth and eye opening and closing are being tested

Medical aids customized by a German medical device company

Originally customized by Australian customers

Masks of middle-aged People in Europe and America are very popular

European and American young people mask, popular young people mask, popular

He is an old farmer in Europe and America, honest, authentic and friendly

Masks for young people in Europe and America, welcomed by customers

The best-selling style in Europe and America it is well received by users

European and American best-selling style, deeply loved by users